Job Methods

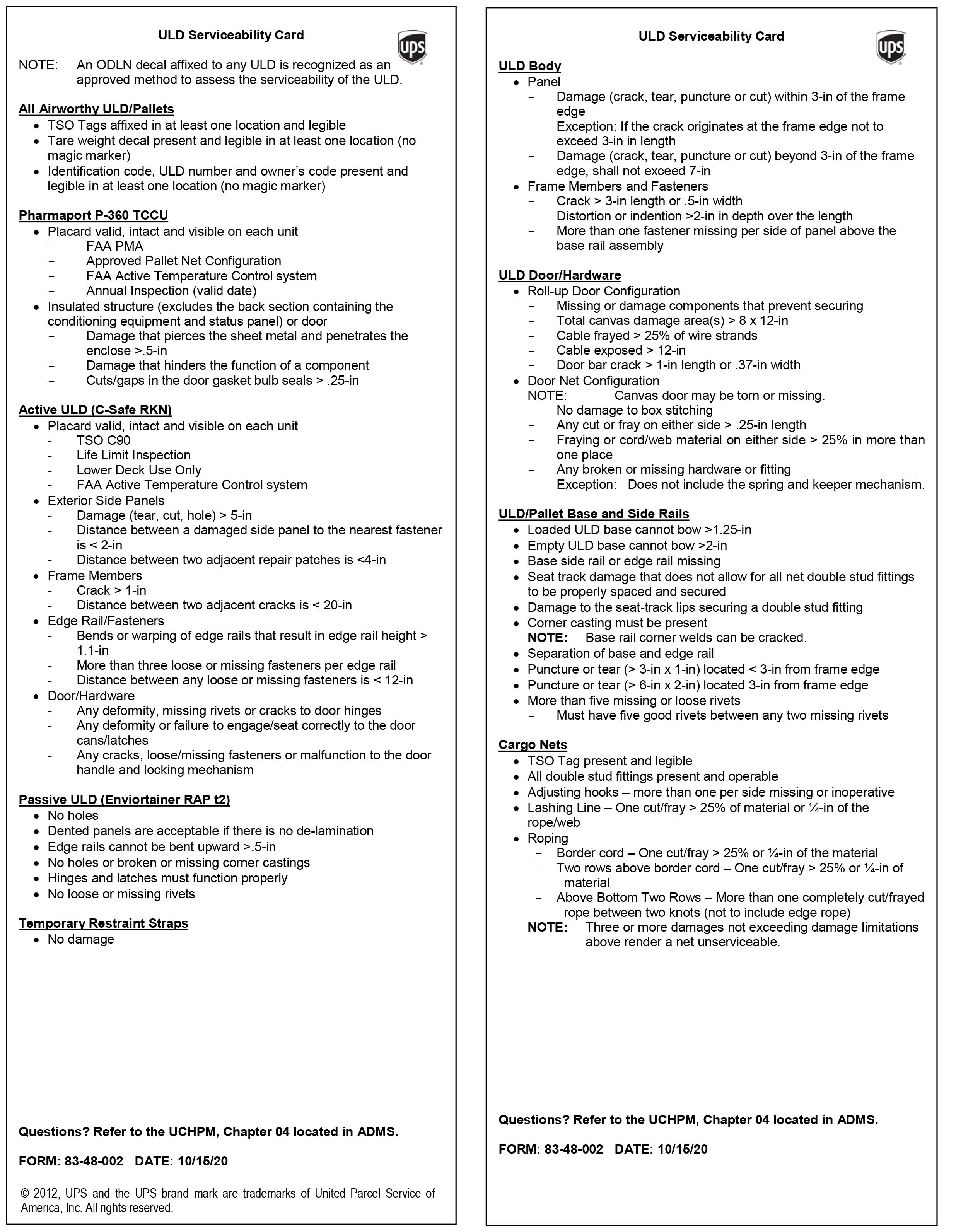

U.L.D. Serviceability Cardexpand_more

For convenience reference only. You are required to know where the physical U.L.D. Serviceability card is in your area.

Container Loadexpand_more

This comprehensive training video covers proper methods and safety guidelines to ensure secure and organized loading.

Container Unloadexpand_more

From handling smalls to team lifting irregs, this video equips you with the necessary skills to excel in the container unloading process.

Feeder Loadexpand_more

Learn the most efficient techniques for loading feeders, ensuring packages are securely braced for smooth transportation.

Feeder Unloadexpand_more

Discover how to safely unload packages from feeders, maintaining a focus on a sense of urgency and proper handling procedures.

Cargo Tractor'sexpand_more

Pre-trip

Controls

Dolly Safety Video

Cargo Loader'sexpand_more

Pre-trip

Controls

Cargo Loader Setup Video

Belt Loadersexpand_more

Pre-trip

Controls

Safety

Wrap Up

- Ensure conveyor surface is off before securing the restraint nets.

- Personnel must walk down the conveyor surface to exit the aircraft.

- Personnel must lower both handrails.

- Personnel must remove chocks.

- Personnel must release parking brake.

- Using a GSE Guideman, back away from the aircraft approximately eight feet.

- At approximately eight feet, lower the conveyor surface to the fully-lowered position.

- Continue backing until the belt loader is outside the aircraft safety perimeter.

Admin Methods: Manifesting Containersexpand_more

1st check

ALP

- Verify new ULD has an "A" Airworthy Status Load Restriction Code & Dry Ice should be blank

- Orig/ Orig Sort-4009D(2DA)/4009N (1DA)

- Dest/ Dest Sort should match manifest

- Verify the Disposition Code for service levels

- 3DA = C, International = I or Postal = P

- Verify ULD has no discrepancies

HMMS

- Verify new ULD contains no dangerous goods = "container does not exist" message.

- Compare manifest to ALP, GSS scanner & ULD #

2nd check

- Close ULD on GSS scannner.

- On Manifest - Fill out percent, piece count & sealed by name

- Verify manitest matches ALP (percent, piece count, comments & SLIC)

International Manifest and DG Load Tag MUST be accompanied with a US. Customs sticker

Admin Methods: Hazmat/Dry Iceexpand_more

- Monitor eHUB for hazmat icon & Watch for DI (Dry Ice) packages

- Check and process harmats immediately

- Update/ View HMMS, eHub & ALP after processing DI and Hazmats

- An envelope MUST be present on the ULD when processing DI and Hazmats

- DI tracking form with ULD # and DI amount is required

- Verify all info on ULD Summary with Validation Sheet

- Print Load Tag and fill out correct container informaton

- Print 3 copies of the ULD Summary & have the LOADER sign first initial & last name on all 3 copies

- Place 2 ULD Summaries (2 shipper declarations for Canada) behind Load Tag in envelope & verify ULD # when placing paperwork on ULD

- Supervisor MUST initial and verify accurate DG paperwork

- After verifying information on Load Tag, close container on GSS scanner

- Complete second check by viewing all info in ALP